Hey guys. My first post on this site but I thought that you might be interested in seeing the results of my latest project. Before I get into that it would probably be a good time to give you a little background into me and my baby.

Just so you're prepared, I want to let you know that I'm really proud of it and everything I've done over the years, so you might as well grab one of your favorite adult beverages, your reading glasses, get really comfy and you might get somewhat entertained. For you guys in the north, it'll be a couple months before you come out of hibernation anyway so you got plenty of time to kill right? So go get ready and let's get started.

I bought my boat way back in '92 after I had skied behind several tournament inboards and fell in love with each and every one of them in some way or another. I am the third owner and when I got it there were around 300 hrs. on it. When I started to look for a boat I only two prerequisits:

1) I wanted something that was different. Namely, not a Correct Craft or Master Craft. Not that they're bad boats by any means. On the contrary, both are really well made very good boats. Whenever somebody gets a boat or any new toy for that matter, what's the first thing that the owner does to it? They personalize somehow to make it unique to any other machine out there. Well I've always been a bit of a rebel so I wanted to start out with something unique.

2) I wanted it to have a Chevy engine. Again, not that Ford is bad. I've been more of Chevy guy my whole life and I just get so tired of everybody asking if it's a 351 Ford. Like that's the defacto standard or something!!! Please. That rebel aspect of my nature is rearing it's ugly head again. Sorry if you're a Ford freak but you're probably not going to enjoy this post too much then.

Anyway, I found this beauty and never looked back. You know the old adage about the two best days of your life.....the day you buy your boat and the the day you sell it......yuk, yuk. Or you know what BOAT stands for...Break Out Another Thousand.......Yeah, yeah, laugh it up fuzzball!!!!! I've heard 'em all just as I'm sure you have.

I now have 1300 hrs on the clock and every minute that I've put on it has been pure pleasure. I've taught my daughter, family, friends and even perfect strangers some form of watersports over the years. Skiing, wakeboarding, kneeboarding, barefoot, wakesurf and even the dreaded tubing. I'm predominantly a barefooter myself and I've taught several dozen people the sport after learning what not to do. This latest project has put it out of commission for three years. My ski partner has a '80 CC Ski Nautique that we used during the old girls decommissioning so it's not like we were without a boat during that time.

My daughter couldn't wait to get it back on the water and at one time told me that some of the best times in her life were when we were together in that boat. Another friends daughter (whom I taught to barefoot when she was eight years old) came to visit us after being gone to college for a year. She said she almost started crying seeing that boat sitting in the driveway and instantly recalling the many memories it brought back. How can you put a price on something like that? Now, I have grandbabies (4 and 2.5 yr. old twins) that I just started teaching to ski. Needless to say, I'll do whatever I have to and spend as much as I need to ensure that I can pass lifelong memories onto them.

Over the last several years I've been quite active at CorrectCraftFan.com. For those of you not familiar, it's a forum very similar to this for CC fans. Even though I don't own a CC, they have accepted me very openly and several of them have stayed at my house, been present at my dinner table and skied with my boat. My current ski partner I met through that website and I've been to several of their reunions. The knowledge base there is nothing short of phenominal and if there is anything that you might want to learn about tournamnet inboards, that's a pretty good place to start. I also know that Ron and Dan here are extremely good and very knowledgeable when it come to AS boats. I had a couple different phone conversations with Ron when he was the owner of the company even though he probably doesn't remember and Dan has spent some time on the CCFan website providing help to others. Even though I have never personally met either one, I have nothing but the utmost respect for them. That being said, I thought that I would try and share some of my experiences with those who are fellow American Skier owners.

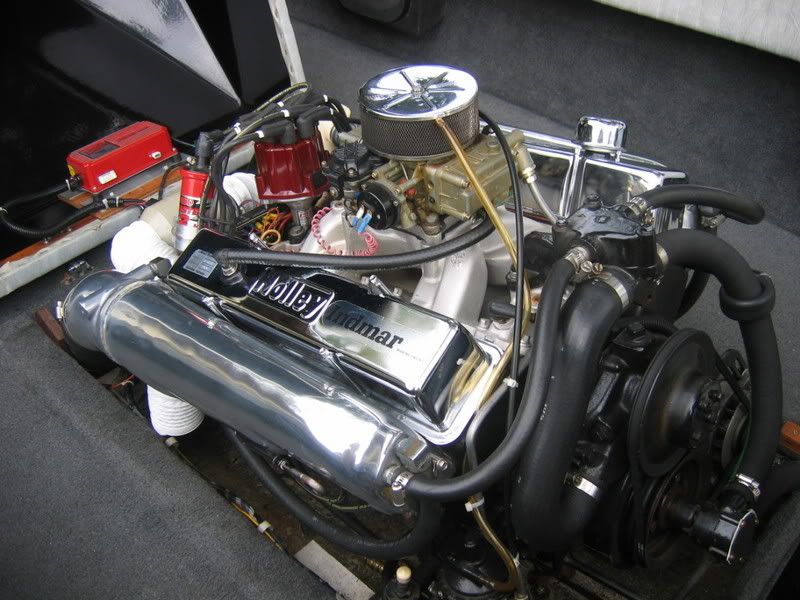

Back about 12-13 yrs. ago I replaced the floor and carpet. I treated everything with CPES (clear penetrating epoxy sealer) so if I did everything right, I shouldn't have to do that again. So far, the floor is as solid as the day I installed it. I also had a cracked head (common for a SBC) so I replaced the stock heads with a set of World Products Torquer II's that I pocket ported and gasket matched to an Edelbrock Performer Air Gap manifold. I also wanted to upgrade to electronic ignition so I put a MSD marine distributor in at that time also. I did some polishing of the exhaust manifolds and have always been very proud whenever the cover was lifted.

So here's a couple of ticklers to what I'm starting with before I kick off the new project.

Yes, this is with almost 1300hrs. on the clock.

So what about this project? Back around feb. of '09, I had some of my wife's family down here and we were enjoying some water time. Her nephew was pulling me on a nice long footin' run and when I dropped off, I heard this real bad knocking sound coming from the boat. I could hear it from 200' away while I was floating in the water. It was one of those sounds that makes your heart sink. The oil pressure and temp were all good so I told him to keep it running. It was coming from the bottom end and was consistant with crank rotation. It definitely wasn't valve train. It wasn't missing or idling rough either. Except for the knock, everything felt and looked perfectly normal. So after idling for a couple minutes, the knock mysteriously vanished. I shut it off and turned it back on several times and it still sounded perfect. The oil was topped off with no signs of water in it. We ran it back to the trailer and loaded it up. The next day, I changed the oil and fired it up in the driveway and again, everything was normal. I took it to the lake the next weekend and as soon as I fired it up, the knock was back. It was now time to tear into it and see what was going on.

Ever since I've had my baby, I always said that whenever it came time to rebuild, I wanted to stroke it to 383. I figured it was the perfect time to do that right? Unfortunately, two weeks later, I had to take almost a 20% pay cut to keep my job, but hey, I still had a job and insurance. We were still OK for paying the bills but there was nothing extra for building a stroker. I quickly realized, there was no way that I was going to be able to do much of anything without some help, so I got a second job bartending. So now I'm starting to save some money for my new project and I also start researching what I really want to do to it.

Now keep in mind that I know enough about engines to be dangerous. I've done the aforementioned things but I've never attempted anything like this. I have learned a lot from the CCFan forum but until you actually do something like this, you never really understand what's involved. I knew that I was in for a real learning experience but at the same time I was determined to do this myself. I started reading books, articles, websites and pretty much everything else I could get my hands on. I had pretty much all the tools I needed but I was still going to have to acquire some specialty items that I didn't have. Things like an engine stand, blast cabinet, a hoist of some sort. I would also need some specialty tools like a tapered ring compressor, degree wheel and several different precision measuring tools just to name a few. As you have probably figured out by now, this was going to be a marathon and not a sprint.

Stay tuned guys. I promise things will get interesting before I'm done.